Read more about Micro Drives? Enter your e-mail address here and you will receive the PDF.

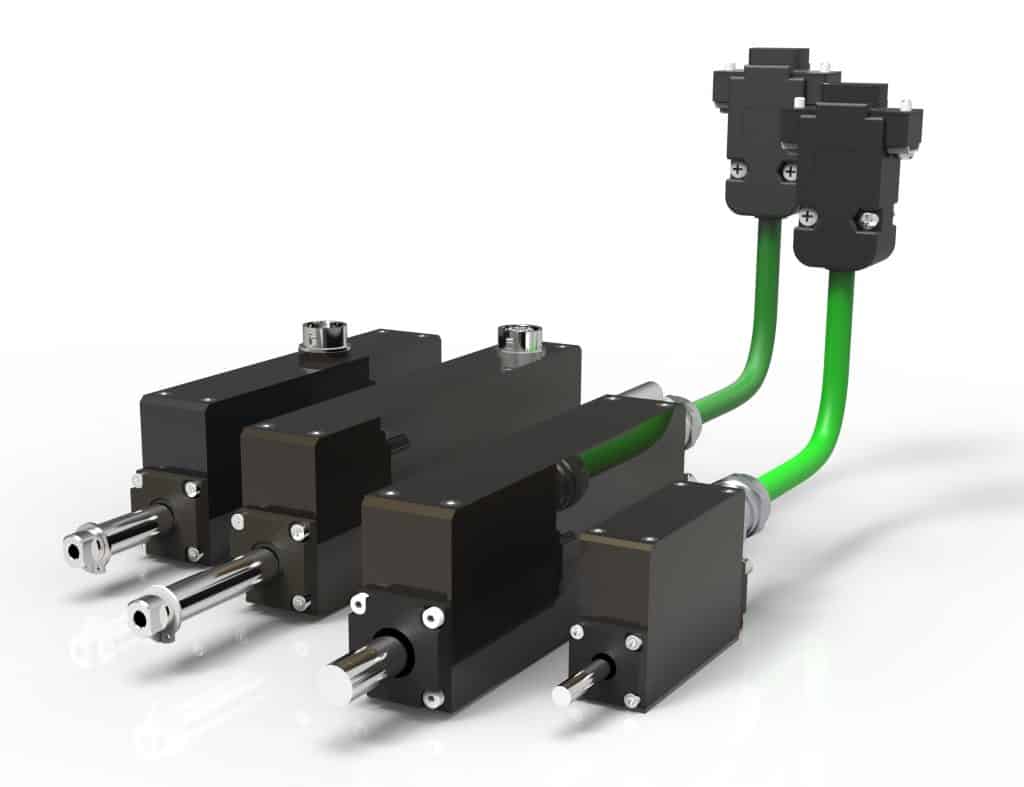

NiLAB Linear Motors

Miniature Linear Motor for pharmaceutical and medical industry

The compact linear motors of NiLAB are, because of their performance and finishing, a complete solution for the pharmaceutical, medical and general machine-industry. This NLH-series is valued for its compactness with flange dimensions starting at 15x34mm up until 35x63mm. The linear motor is composed of a high performance three phase winding, an integrated encoder SIN/COS 1Vpp and a rod in AISI 304 stainless steel. The NLH series, composed of 6 different types, has an excellent performance and dimension ratio. The force range starts from 0,6 N up to 20 N of continuous force with peak forces 6 times these values. The standard power supply of the drive is 24/48 VDC.

The most important factor that makes this series of motors interesting for the food- and pharmaceutical industry, is the finishing with the G.H.A.®-coating. This is one of the most advanced and innovative technologies used for the treatment of aluminum alloys. The surface of the aluminum alloy is first treated by anodic oxidation with a thickness of 10 to 200μ, followed by a seal of the micro pores of silver ions (Ag+). Anodic oxidation is the most appropriate, protective treatment for aluminum alloys, because this can’t be removed. The G.H.A.®- process (Golden anodized) is patented (patent EP1207220).

The advantages of G.H.A.® treatment

- Highest corrosion resistance

- High antibacterial- and anti-fungal performance (bactericidal)

- Anti-static

- High thermal conductivity

- High heat resistance

- High abrasion resistance and hardness (500-600 HV)

- Suitable for direct contact with food

Aluminum alloys with G.H.A.®-treatment are in most cases an excellent alternative to expensive alloys such as titanium alloys or stainless steel. The motors of the NLH-series, with the innovative G.H.A.®-coating are very interesting to use in the food- and pharmaceutic industries.